State of the art

Once again, we have managed to redefine fire safety for industrial kitchen exhaust air. In the fire protection closure we implemented our customers' requests for the shut-off device to be constructed smaller and more lightweight while increasing the unrestricted cross-section.

Due to its 100% unrestricted cross-section, the FIRESAFE II K90 does not have any additional pressure loss nor do fat particles have a chance to adhere to the clamping area. This makes it possible to keep the cleaning expenditure as well as the operating costs as low as possible.

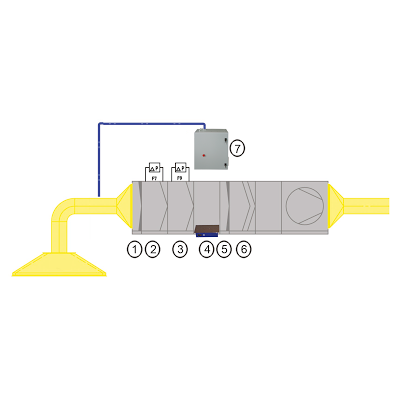

When exceeding the operation temperature in the exhaust line (72° C), the device will close currentless after shutting off the exhaust air fans. The possibility of re-inflammation or suction inside the duct system is eliminated almost completely. Aditionally, in the case of gas fired hobs, the magnetic valve will close which causes the gas flow to get interrupted. As a result, the chance of undergrate firing of the resulting fire is eliminated. Depending on the cross-section's size, the exhaust line will be closed smoke- and fire-proof. Further signals can be directed toward the building control system or central fire alarm system via the built-in limit switches with potential-free contacts.

The installation of the FIRESAFE II K90 into massive walls, ceilings, light partition walls and fire walls, through which inddustrial kitchens' exhaust air pipes are led, the L90 covering of the lines can be foregone. This asset is gaining more and more importance, especially when it comes to restructuring measures.

FIRESAFE II K90 - innovation for your kitchen exhaust air